|

|

Shaft Mounted Speed

Reducer (SMSR) |

|

|

|

Send Enquiry

In Stock SMSR Gearboxes

AGNEE Shaft Mounted Speed Reducer (SMSR) is one of the most versatile drives

offering the largest ratio range and capable of powers up to 280kW.

|

|

Features

Model in 7 sizes B, C, D, E, F, G, H with nominal gear ratios of 5:1, 13:1

and 20:1

Extended 2 year warranty (optional).

Mounts direct onto the driven shaft:

- No alignment problems.

- No shaft couplings.

- Flexible motor mounted in a convenient position.

No expensive adjustable base plate is required for the motor, as

V-Belt

tensioning is done by the use of a torque arm which can

be simply shortened or

extended to swing the shaft mounted speed reducer about

its output hub to tension the 'V' -Belts.

Quick and easy speed changing via belt drive.

Final output speed can be very accurately obtained by adjusting the 'V'

-Belt'

drive ratio.

High efficiency by using helical gears

- Single - 98% efficiency.

- Double - 96% efficiency.

Anti-run back device can easily be fitted on site.

Most shaft mounted speed reducers (SMSR) use "6000" series I. S. O. plan

Taper Roller Bearings, stocked around the world.

Double lip type oil seals used throughout in shaft mounted gearbox.

Shaft Mount Gear boxes can be mounted in any position.

Proven history of success in all industrial applications; particularly,

conveyors & elevators in the construction industry.

Long established and proven drive system.

Wide range of variation available:

- Shaft mount, face mount, foot mount, motor mount, hydraulic input, screw

conveyor adaptor.

Shaft Mounted Speed Reducers (SMSR) are ultra compact when compared to other designs.

AGNEE offers a full comprehensive repair facility including spares

availability for shaft mounted gearboxes.

|

Shaft Mounted Speed Reducer

(SMSR)

Profile grinding of Gear

tooth Flank

|

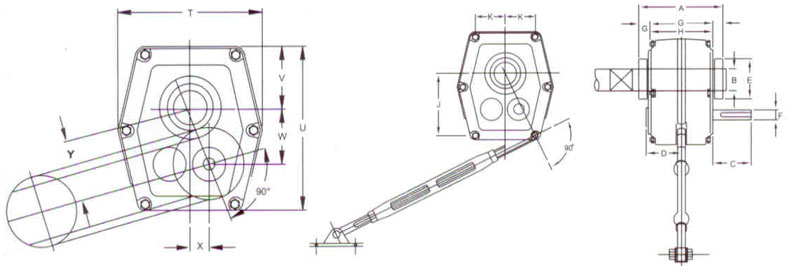

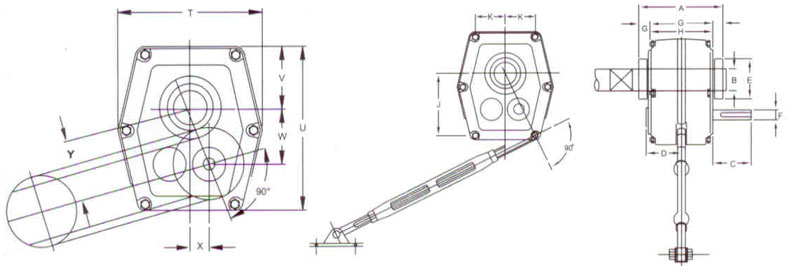

Dimension chart for SMSR-Shaft Mounted Speed Reducer-Sizes B

to H

|

SIZES |

A |

B

|

C |

D |

E |

F |

Input Shaft Keyway |

H |

J |

K |

P |

T |

U |

V |

W |

X |

Y |

|

Hub Dia |

|

STD |

ALT |

|

B |

134 |

30 |

40 |

63 |

59 |

80 |

19j6 |

6x3.5x50 |

104 |

131 |

55 |

10 |

186 |

226 |

81 |

75 |

25 |

79 |

|

C |

142 |

40 |

50 |

72 |

65 |

90 |

22j6 |

6x3.5x5.6 |

108 |

156 |

59 |

10 |

218 |

270 |

96 |

90 |

31 |

95 |

|

D |

152 |

50 |

55 |

77 |

68 |

100 |

25j6 |

8x4x63 |

118 |

188 |

76 |

12 |

258 |

328 |

117 |

110 |

37 |

116 |

|

E |

170 |

55 |

65 |

85 |

76 |

115 |

28j6 |

8x4x70 |

130 |

222 |

90 |

12 |

278 |

377 |

129 |

125 |

43 |

133 |

|

F |

189 |

65 |

75 |

90 |

87 |

130 |

32k6 |

10x5x70 |

149 |

242 |

98 |

16 |

317 |

414 |

143 |

141 |

50 |

150 |

|

G |

212 |

75 |

85 |

105 |

110 |

145 |

42k6 |

12x5x90 |

172 |

277 |

110 |

16 |

365 |

468 |

162 |

156 |

56 |

166 |

|

H |

242 |

85 |

100 |

116 |

115 |

170 |

48K6 |

14x5.5x100 |

190 |

330 |

88 |

16 |

434 |

550 |

195 |

189 |

62 |

200 |

Power Rating (KW)

|

OUTPUT

RPM |

B5 |

C5 |

D5 |

E5 |

F5 |

G5 |

H5 |

J5 |

|

50 |

1.35 |

2.50 |

3.85 |

5.55 |

8.30 |

12.10 |

19.30 |

31.50 |

|

100 |

2.69 |

4.60 |

6.30 |

11.20 |

16.50 |

25.20 |

39.00 |

61.00 |

|

150 |

3.60 |

5.70 |

8.90 |

14..00 |

20.00 |

35.00 |

50.40 |

78.00 |

|

200 |

4.30 |

6.70 |

10.50 |

16.60 |

24.00 |

40.00 |

60.00 |

93.00 |

|

250 |

4.60 |

7.70 |

12.00 |

18.00 |

27.50 |

46.00 |

68.00 |

107.0 |

|

OUTPUT

RPM |

B13

B20 |

C13

C20 |

D13

D20 |

E13

E20 |

F13

F20 |

G13

G20 |

H13

H20 |

J13

J20 |

|

10 |

0.29 |

0.50 |

0.80 |

1.30 |

1.90 |

3.30 |

4.70 |

7.45 |

|

20 |

0.60 |

1.10 |

1.70 |

2.50 |

4.10 |

7.00 |

10.00 |

15.80 |

|

30 |

0.80 |

1.70 |

2.60 |

4.20 |

6.20 |

10.50 |

15.00 |

24.00 |

|

40 |

1.15 |

2.20 |

3.50 |

5.50 |

8.10 |

14.00 |

20.00 |

31.00 |

|

50 |

1.40 |

2.50 |

4.00 |

6.30 |

9.40 |

16.00 |

23.00 |

36.00 |

|

60 |

1.70 |

3.00 |

4.70 |

7.40 |

11.10 |

19.00 |

27.00 |

42.5 |

|

70

|

1.90

|

3.30 |

5.20 |

8.25 |

12.10 |

21.00 |

30.00 |

46.00 |

|

80 |

2.20 |

3.90 |

6.15 |

9.65 |

14.20 |

24.50 |

35.00 |

54.00 |

|

90 |

2.40 |

4.40 |

6.80 |

10.70 |

15.70 |

27.00 |

39.00 |

60.00 |

|

100 |

2.70 |

4.60 |

7.20 |

11.30 |

16.60 |

28.50 |

41.00 |

63.50 |

|

TORQUE

AT 10RPM

in NM |

275 |

510 |

810 |

1270 |

1865 |

3230 |

4650 |

7100 |

|

TORQUE

AT 70 RPM

in NM |

260 |

420 |

740 |

1120 |

1790 |

2950 |

4550 |

6600 |

|

For speed higher than 70 rpm output use 1:13 or 1:5

ratios

Applications:

SMSR’s Have Diverse Application in Material Handling

Equipment (Conveyors, Elevators)

Industries Covered:

Cement, Coal, Steel And Engineering Industries, Textile

Processing Industries, Sugar Mills, Food Processing And Dairy Plants,

Drugs & Pharmaceutical Plants And Printing Machinery

<<back |

|

|

|

|