|

|

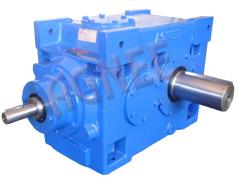

Helical & Bevel Helical Gearbox

Product Specification |

Features | Applications

H Series Bevel Helical Gearbox and

Helical Gear Box:

Send Enquiry

AGNEE H series helical parallel shaft and bevel helical right angle

drive industrial gearboxes have been introduced to meet the requirements

of today's demanding applications in the medium and heavy-duty sector of

the power transmission market.

The modular design and construction of the Series H offers many

engineering and performance benefits including a high degree of

interchangeability of parts and sub assemblies. This in turn provides

considerable economies of production while maintaining the highest

standard of component integrity.

Apart from standard range, Gear Boxes are also tailor made to suit

individual requirement or as per specifications provided. Please feel

free to discuss your requirement and we shall be pleased to make

suitable suggestions.

Product Specification:

Gear tooth geometry design combines

maximum efficiency with high load carrying capacity and minimal noise

generation. Serviceability of the product was key in the design of the

Series H range allowing easy maintenance for long life and reliability,

which are synonymous with our field reputation.

-

Unit Sizes: 80, 90, 100, 112, 125, 140, 160, 180, 200,

225, 250, 280, 315, 355, 400, 450, 500, 560, 630

-

Transmission ratio: 1.2 - 637

-

Input Power: 0.61 KW to 5,000 kW

-

Torque: Up to 117,000 Nm

For Bevel Helical Geared Motor

Click Here

|

|

|

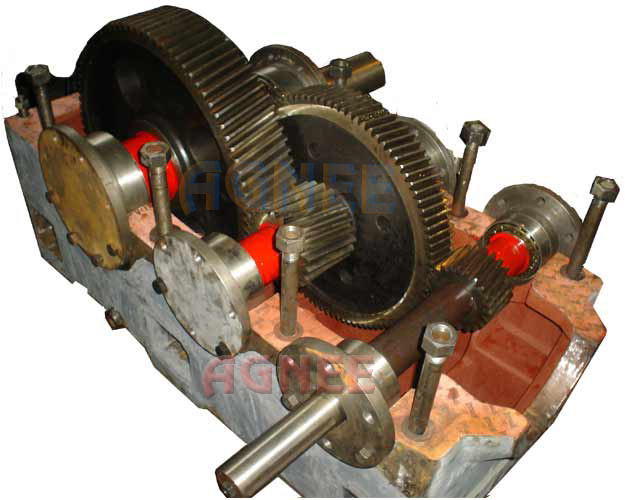

The Helical & Bevel Helical Gearbox Housings are usually made of Close Grain Cast

Iron. Sometimes Housing is also offered in Structural Steel when the

application demands. They are rugged, corrosion resistant and absorb

shock and vibration. The Helical Pinion is made of EN 353 Case Hardening

Steel, Helical Gears are made of SAE 8620 Case Hardening Steel. The

teeth are generated on Gear Hobbing Machine. They are then Case

carburized, Hardened and Tempered. Finally, they are surface ground to

close tolerances. The teeth Flanks are ground on Teeth Profile Grinder.

This leads to very good efficiency and a quiet working condition. The

Output shafts are from alloy steel forging or bars. Low speed shafts can

be solid or hollow type. Bearings are fitted on a accurately bored

journal and taper roller Bearings are used.

Features & Benefits of Bevel Helical Reduction Gearboxes :

AGNEE

Series H Bevel Helical Gearbox takes advantage of our many years of

accumulated design expertise together with the use of high quality

materials and components, and has the following features & benefits:

- Profile ground helical gears.

- High level of surface finish for quiet running.

- All Gears and Pinions case carburised, Hardened and Tempered

- Teeth Profile Ground

- Units can be offered in horizontal or vertical mounting positions

- All units are also available with hollow bore for output shaft

mounting.

- Output bores can be connected by shrink disc.

APPLICATIONS:

(i). Standard Application:

Our Bevel Helical Geared Motors are widely used in applications > 50KW, Agitators, Conveyors, Crushers, Cranes, Larger

Ball Mills, Mixers, Aerators, Fin Cooler Drives, Kneaders, Thickeners

Case hardened and Profile ground Steel

Gears with inclined tooth to transmit the torque between parallel /

Right Angle shafts with minimum noise.

Industries Covered

are - Sugar, Cement, Paper, Solvent Extraction, Rubber, Steel Industry,

Power Plants, Mines and Minerals, Chemical

(ii). Special App. Helical Gear Reducer & Bevel Helical Gearbox

Cooling Tower and Heat Exchanger

Case Hardened and Lapped steel spiral bevel gears to transmit the torque

between right angle shaft. Unicase design with Pumpless Lubrication and

three-point Foundation.

Industries Covered

are - Sugar, Cement, Paper, Solvent Extraction, Steel Industry,

Power Plants.

<<back

|