|

Gear

Couplings

Nylon Gear Couplings

Star Jaw Couplings

Curved Tooth Flexible Gear Couplings

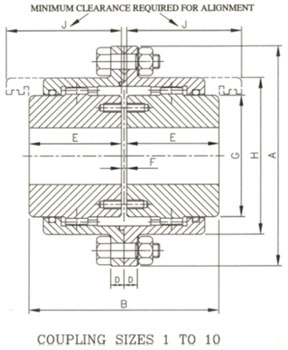

AGNEE Gear Couplings are distinguished by their mechanical flexibility

and compensation of Angular, Parallel and Axial misalignments of the

connected shafts. Gear Couplings are made for extensive use in Metal

Rolling Mills, Paper Machinery, Cranes, Dredgers, Rubber and Plastic

Industries, Cement Plants, Conveyors and Elevators, Compressors, Fans

and Blowers, Screens and other general industries. Flexible Gear

Couplings basically consist of two hubs, with crowned external teeth and

two outer sleeves with internal spur teeth.

|

|

|

|

|

|

|

|

FEATURES: Gear Hubs and the outer sleeves are manufactured from carbon

steel and are hardened to the required degree. They are machined to fine

tolerances for proper meshing of the gears as well as for

inter-changeability.

HUBS : The teeth of Gear Hubs are crowned and are generated by involute

system. The amount of crowning and backlash values are so chosen as to

ensure the best results in torque transmission, greater flexibility and

smooth operations.

SLEEVES : The internal teeth of the sleeves are produced in gear shaper

ensuring the correct profile. These teeth are also generated by involute

system.

The coupling sleeves are joined together with high tensile steel (class

8.8 IS : 1367) fitted bolts.

'O' RINGS : The setting of special 'O' Rings at the ends of coupling

hubs prevents leakage of lubricants and entry of dust. The 'O' rings can

also withstand high degree of O temperature upto 120 C.

POWER RATINGS :The normal power ratings are given in the Table. For

selection of the correct size of couplings, proper service factor

depending on the type of machines and the peak load should be

considered.

SERVICE FACTOR :Generally, for medium duty use a service factor of 1.5.

For heavy duty use a factor of 2 and for extra heavy duty a factor of 3

should be used. For special applications please contact AGNEE with full

details.

LUBRICATION :The coupling must be filled with grease or oil. It is

recommended to use grease where the maximum temperature is within 80

degree C and for temperature above 80 degree C, oil should be used.

When using grease it is suggested to fill the coupling completely

with Lithium based grease with EP additives (NLGI-No.1 consistency).

When the coupling is to be filled with oil, fill half the coupling with

EP Gear Oil.

RECOMMENDATION FOR GREASE & OIL:

Grease : Indian Oil - Servogem - EP 1 or equivalent.

Oil : Indian Oil - Servomesh SP 680 or equivalent.

Features:

High Torque Rating

Large Bore Capacity

Interchangeability

Improved Lubrication System

Better Fastener Design

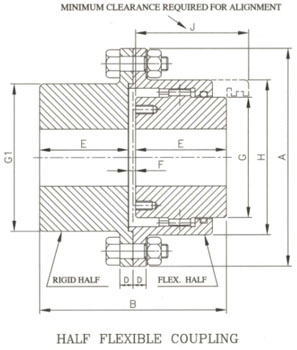

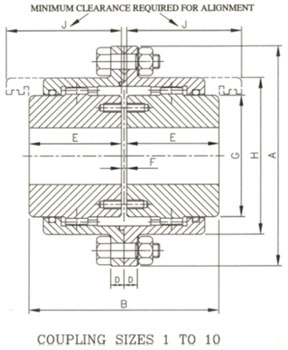

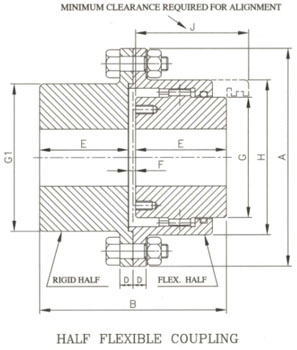

Power rating and Dimensional Details in mm

|

|

|

Coupling No.

NO. /SIZE |

H.P.

per 100 rpm |

Torque

rating

in Kgm |

Hub

Bore |

Max.

Speed

RPM |

Dimensions MM |

Weight in Kgs |

Approx. GD^2 Value Kg m^2 |

No.

of Bolts

|

Amount

Grease / Oil

|

|

Flexible |

Half |

|

Max. |

Max. |

A |

B |

D |

E |

F |

G |

G1 |

H |

J |

Kg. |

Ltr |

|

AGC-0 |

7 |

50 |

35 |

50 |

8000 |

120 |

93 |

15 |

45 |

5 |

50 |

70 |

75 |

55 |

4.2 |

0.14 |

6 |

0.2 |

0.2 |

|

AGC-1 |

14 |

100 |

50 |

60 |

6300 |

170 |

115 |

17 |

55 |

5 |

65 |

85 |

110 |

65 |

10.5 |

0.21 |

6 |

0.3 |

0.25 |

|

AGC-2 |

35 |

250 |

60 |

75 |

5000 |

185 |

145 |

17 |

70 |

5 |

85 |

110 |

125 |

85 |

15 |

0.45 |

6 |

0.6 |

0.5 |

|

AGC-3 |

63 |

450 |

75 |

90 |

4000 |

220 |

175 |

20 |

85 |

5 |

105 |

130 |

150 |

105 |

26 |

0.98 |

6 |

1 |

0.7 |

|

AGC-4 |

119 |

850 |

90 |

110 |

3300 |

250 |

215 |

20 |

105 |

5 |

130 |

160 |

178 |

125 |

42 |

1.90 |

8 |

1.5 |

1.5 |

|

AGC-5 |

182 |

1300 |

110 |

130 |

2800 |

290 |

240 |

25 |

115 |

10 |

155 |

185 |

204 |

140 |

63 |

3.05 |

8 |

2.5 |

2 |

|

AGC-6 |

280 |

2000 |

125 |

150 |

2500 |

320 |

260 |

25 |

125 |

10 |

175 |

215 |

230 |

155 |

87 |

5.25 |

8 |

3 |

2.5 |

|

AGC-7 |

490 |

3500 |

140 |

170 |

2100 |

350 |

290 |

25 |

140 |

10 |

205 |

240 |

260 |

175 |

120 |

8.52 |

10 |

3.5 |

3 |

|

AGC-8 |

630 |

4500 |

160 |

200 |

1900 |

380 |

330 |

25 |

160 |

10 |

230 |

285 |

290 |

200 |

170 |

15.00 |

12 |

4.5 |

4.5 |

|

AGC-9 |

784 |

5600 |

180 |

220 |

1700 |

430 |

340 |

25 |

165 |

10 |

250 |

315 |

332 |

210 |

220 |

28.67 |

10 |

6 |

6 |

|

AGC-10 |

1148 |

8200 |

220 |

260 |

1400 |

490 |

370 |

25 |

180 |

10 |

310 |

370 |

390 |

230 |

320 |

52.00 |

12 |

8.5 |

8 |

|

|

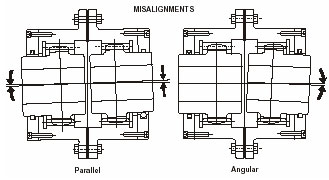

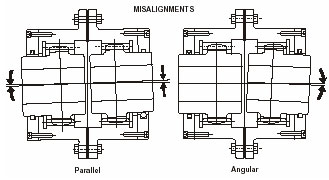

MISALIGNMENT: The crowing of the teeth

allows the coupling to withstand parallel misalignment upto a

maximum of 10.25 mm and angular misalignment upto a maximum of ±

1.5 per gear mesh. The coupling can also absorb axial displacement

of the shafts upto a maximum of ± 3 mm. |

|

|

|

FOR SELECTION OF THE COUPLINGS, THE FOLLOWING DETAILS ARE

REQUIRED :

1. Type of driven machine.

2. Power absorbed by the driven machine and Peak load.

3. Speed and Diameter of the connecting shafts space available for

accommodating the coupling.

4. Maximum misalignment to be compensated.

5. Surrounding temperature.

6. Any other special feature of the drive.

Example : A gear couplings is required to transmit 250 KW from an

Electric Motor running at 730 rev/min to a Pulper Machine.

Considering the peak load as 180% of full load, the Motor shaft as

100 mm and the Pulper shaft as 110 mm, select a suitable gear

coupling.

a) Service factor : 2 (for heavy duty application)

b) Peak load : 180% of full load.

c) Design power : 250 x 180/100 x 2 = 900 KW

d) Power to be transmitted at 100 rev/min : 900 x 100 / 730 =

123.3 KW

e) Coupling size : By referring to the Table coupling size NGC 5,

has got a rating of 150 KW at 100 rev/min which exceeds the

required power of 123.3KW. The bore range is 60 mm to 110 mm.

Hence, size AGC 5 is selected for the application.

<<back |

|

|

|

|