|

|

|

|

|

Journal Bearings

|

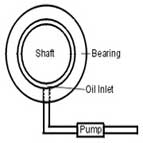

Journal Bearing (Oil filmed Bearings):-

A journal bearing, simply stated, is a cylinder which surrounds the

shaft and is filled with some form of fluid lubricant. In this

bearing a fluid is the medium that supports the shaft preventing

metal to metal contact. The most common fluid used is oil, with

special applications using water or a gas. This application note

will concentrate on oil lubricated journal bearings.

|

|

Hydrodynamic Bearing:-

A Hydrodynamic Bearing, which are active as the shaft rotates, create an

oil wedge that supports the shaft and relocates it within the bearing

clearances. In a horizontally split bearing the oil wedge will lift and

support the shaft, relocating the centerline slightly up and to one side

into a normal attitude position in a lower quadrant of the bearing. The

normal attitude angle will depend upon the shaft rotation direction with a

clockwise rotation having an attitude angle in the lower left quadrant.

External influences, such as hydraulic volute pressures in pumps or

generator electrical load can produce additional relocating forces on the

shaft attitude angle and centerline position.

|

|

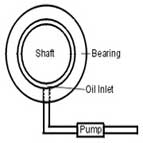

Hydrostatic Bearing:-

Hydrostatic bearings provide accurate, highly damped, friction free linear and

rotary motion. These bearings also average the form errors of the surfaces that

make up the bearing components. This averaging allows the bearings to exhibit

smaller error motions than would otherwise be possible. The small error motions

attainable when hydrostatic bearings are used make them the bearing technology

of choice for ultra precise ways and spindles for instruments and machines.

Hydrostatic bearings are used when operating conditions require full film

lubrication that cannot be developed hydro dynamically. The hydrostatically

lubricated bearing is supplied with lubricant under pressure from an external

source. Advantages of the hydrostatic bearing over bearings of other type are

lower friction, higher load capacity, higher reliability, and longer life.

Hydrostatic bearings rely on an external pump. The power for that pump is

arguably part of overall bearing friction. Better seals can reduce leak rates

and pumping power, but may increase friction. |

|

<<back |

|

|

|

Products

Worm Gearbox |

Helical Gearbox |

Bevel

Helical Gearbox

| Bevel

Helical Geared Motor |

Inline Helical Geared Motor | Planetary Gearbox

| Crane Duty Helical Gearboxes

| Industrial

Gearboxes | Custom Gearbox |

Helical and Bevel Helical Gear

Box

|

Shaft Mounted Speed Reducer

| Double Reduction Worm Gearbox | Sugar

Crystalliser Drive |

Bevel

Planetary Gearbox |

Worm Shaft and Worm Gears Drives | Hydro Mechanical Equipments |

Spur Gears | Helical Gears |

Double Helical Gears | Internal Gears

|

Couplings

Industrial

Resources |

Technical Articles

| Articles Helical Gears

Capacity Ratings

Agnee

Bevel Helical Gearboxes |

Application Areas of Gearboxes

Home |

About Us |

Careers |

Contact Us |

Complaint

| Warranty

Industries we serves include Sugar, Cement, Paper, Solvent Extraction,

Rubber, Steel Industry, Power Plants, Mines and Minerals, Chemical, Elevator,

Textile,

Plastic & leather, Waste water treatment, Food & tobacco.

© 2013

Agro

Engineers

. All rights reserved. Contact webmaster.

|

|